DataOps

Optimise industrial operations by driving more value from data. Apply DataOps to enhance design, deployment, and governance for all data-reliant processes.

Achieve tangible business results faster

Put higher-quality analytics at your fingertips

Enhance the accuracy and integrity of planning and operational data, and make it accessible to all key stakeholders so teams can make more confident decisions.

Generate remarkable insights in less time

With all of your critical apps, data, and people connected, you gain a more comprehensive view of key metrics – and are better positioned to drive valuable insights faster.

Ramp up efficiency to drive down marginal costs

Implement data-driven workflows that help streamline efforts like schema design, data modelling, and work process design. The resulting efficiencies will reduce costs across the enterprise.

Access powerful DataOps capabilities for the Industrial Work Surface

Data Modelling Toolkit

Data Portal

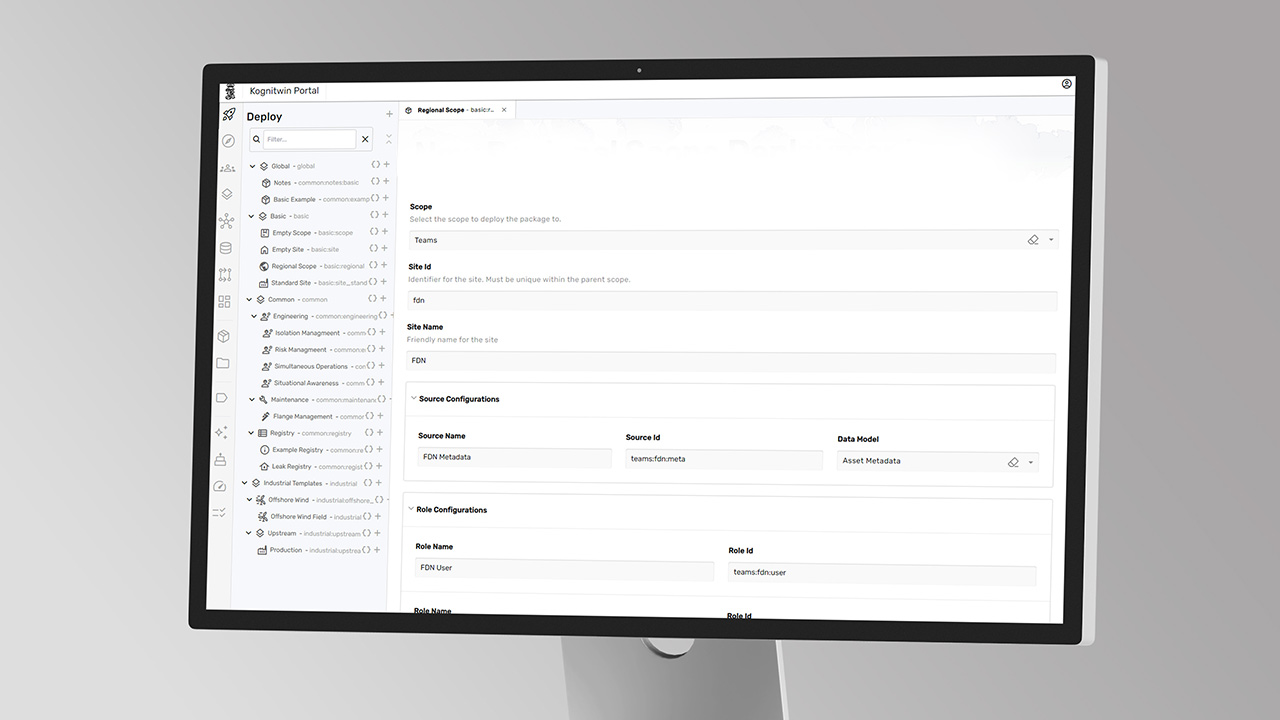

Data Mesh Portal

Data Governance Portal

Data Modelling Toolkit

Want to start making sense of your data faster? Our Data Modelling Toolkit offers a powerful, standardised way to describe data models and then apply these to both existing and new data. Advanced features include semantic and ontology support, graph and relationship aspects, and configurable storage and indexing.

See why industrial leaders are adopting the Industrial Work Surface

This is really changing the way that engineers get work done. The speed of change in our industry requires us to think differently, act differently and support each other differently to have more impactful results in meeting the world's energy needs.

Keith Johnston, Manager Digital Engineering, Chevron

We benefit from the real-time data and use it to enhance operational safety and improve drilling efficiency. In two years, the solution alone has prevented over $200 million in stuck casing incidents.

Fereidoun Abbassian, Vice President Technology, BP

In drilling, any unplanned stop implies a very high cost. With SiteCom we know what happens real-time.

Renata Martin, Head of Inwell Control Center, Repsol

This new way of working will enable our teams to learn from past events, predict future events, and prescribe a path forward to optimise production and equipment performance automatically, maintaining safe and energy-efficient operating parameters without manual intervention. The Industrial Work Surface is the cornerstone to our future ambitions.

James Maguire, Business Transformation Manager, LNG Canada

By integrating all our systems and data into one platform, the digital twin empowers us to improve the risk assessment of all activities at Nyhamna. It helps us achieve our goal of having zero incidents or leaks.

Torstein, Shift Supervisor, Nyhamna, Shell