Kognitwin Simulation

Cloud-native access to advanced simulation engines facilitating the modelling of dynamic production processes, multiphase flow, and control systems, ensuring continuous improvement and adaptation to evolving industry needs.

Simulation-driven operational excellence

Cloud-native access to advanced simulation engines facilitating the modelling of dynamic production processes, multiphase flow, and control systems, ensuring continuous improvement and adaptation to evolving industry needs.

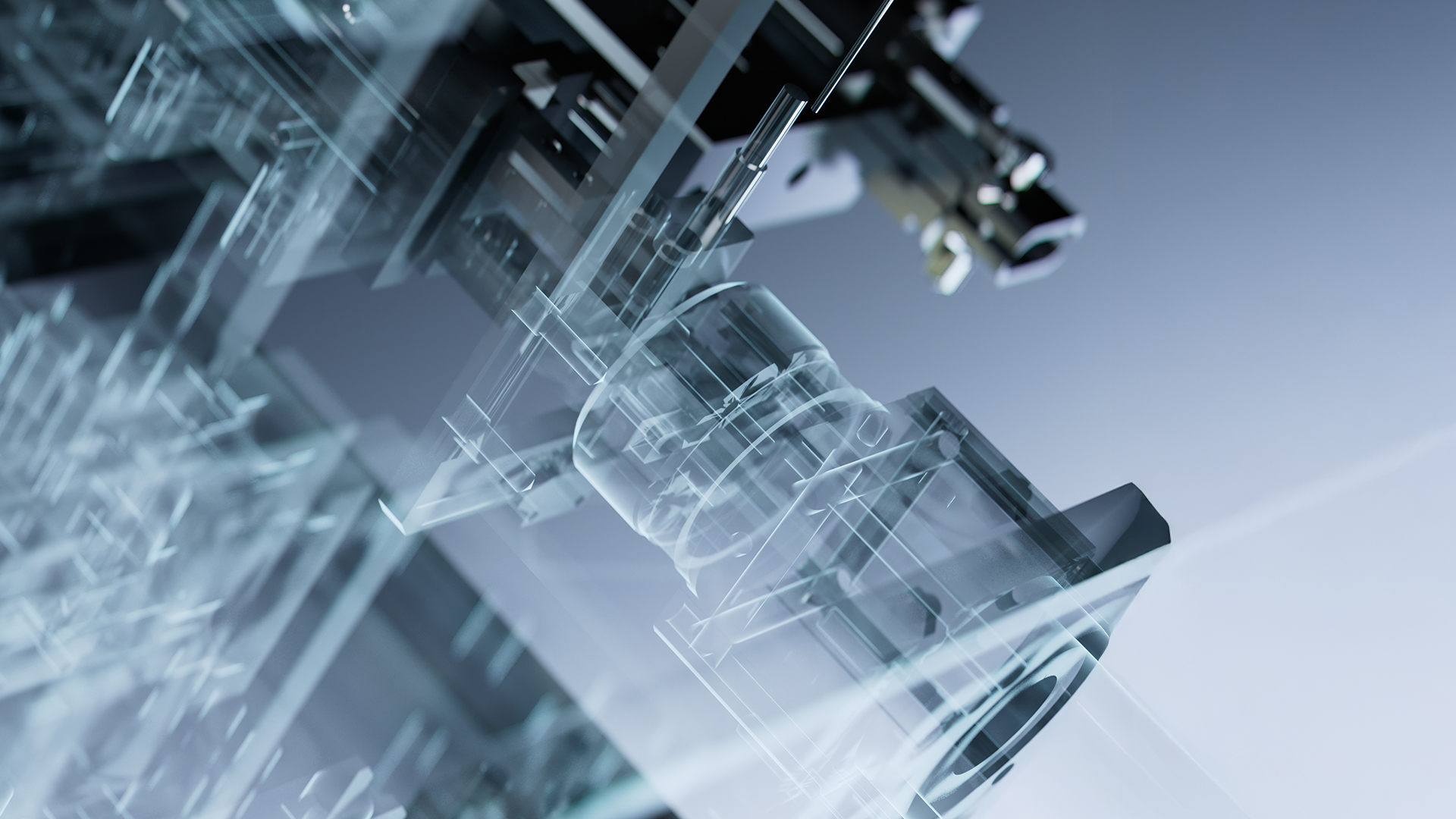

Advanced simulation with digital twin technology to generate more value

Model and simulate production processes and assess control systems with state-of-the-art dynamic simulators for actionable insights and control.

Supercharge productivity through better engagement with your assets

Generate more value by connecting data, people, and workflows

Insights and solutions

High-fidelity simulation

Condition monitoring

Insights and solutions through digital models

Heavy-asset industries face critical challenges including downtime, inefficiencies, emissions, energy consumption, and training needs, impacting productivity and profitability.

Kognitwin Simulation addresses these challenges by leveraging cutting-edge digital twin technology and simulation engines to create high-fidelity 2D and 3D models of facility assets.

These models empower operators with unparalleled insight and control, enabling them to visualise, manage, and optimise real-time operations from anywhere.

Maximise business performance and drive more value

Built with our proven technology, the Industrial Work Surface is already delivering measurable value to organisations in the energy, utilities, renewables, and chemicals sectors.

3 months

Time to value

An asset has a typical digitisation time of 3 months, enabling rapid scaling across the enterprise.

85%

Users are more efficient

With one system to plan, execute and close out work, 85% of users feel more efficient.

20,000+

Users, worldwide

At-scale delivery of digital twin technology to integrated energy companies.

Simulation in digital twins

K-Spice

Dynamic process simulation software enabling detailed engineering tasks, including process design verification, control and safety analysis, debottlenecking, and design optimization.

LedaFlow

Advanced transient multiphase flow simulator designed to optimise continuous flow for oil, gas, CO2, hydrogen, and steam.

Kognitwin Simulation

Empowering operators with a virtual representation of their assets, enabling them to simulate and analyse facility behaviour before implementing changes.