Kognitwin

An advanced digital twin solution– where you can get a holistic overview of your operations and manage workflows through one work surface, 24/7.

Maximise business performance with Kognitwin

An advanced digital twin solution– where you can get a holistic overview of your operations and manage workflows through one work surface, 24/7.

Power workflows with digital twin technology to generate more value

Designed to unify data, streamline workflows, and enhance cross-team collaboration, Kognitwin transforms design validation, simulation, and operational execution across the entire value chain. From upstream to downstream, this cloud-based platform delivers real-time insights, advanced analytics, and contextualised data to accelerate decision-making, enable remote assistance, and support more autonomous, data-driven operations.

Generate more value by connecting data, people, and workflows

Kognitwin facilitates a virtual environment where your industrial data can be accessed, analysed, and actioned across all business areas.

Kognitwin combines advanced machine learning and physics-based simulation to deliver real-time monitoring, predictive insights, and intelligent scenario modelling. Its AI-driven Asset Copilot, together with a team of AI agents, acts as a digital partner, analysing data, optimising workflows, and enabling natural interaction via text, voice, or visuals.

Asset-intensive companies use Kognitwin daily to enable better decision-making, maximise business performance, and drive value across the organisation.

Kognitwin helps break down operational and project silos by providing a single source of truth for key stakeholders across business units. By breaking down data silos and enabling intuitive interaction, Kognitwin empowers faster, smarter decisions across your operations.

Utilise cloud-native simulation technology to digitally visualise and contextualise field production operations from any location, 24/7.

Supercharge productivity through better engagement with your assets

Situational awareness

Augmenting your workers with AI

Production optimisation

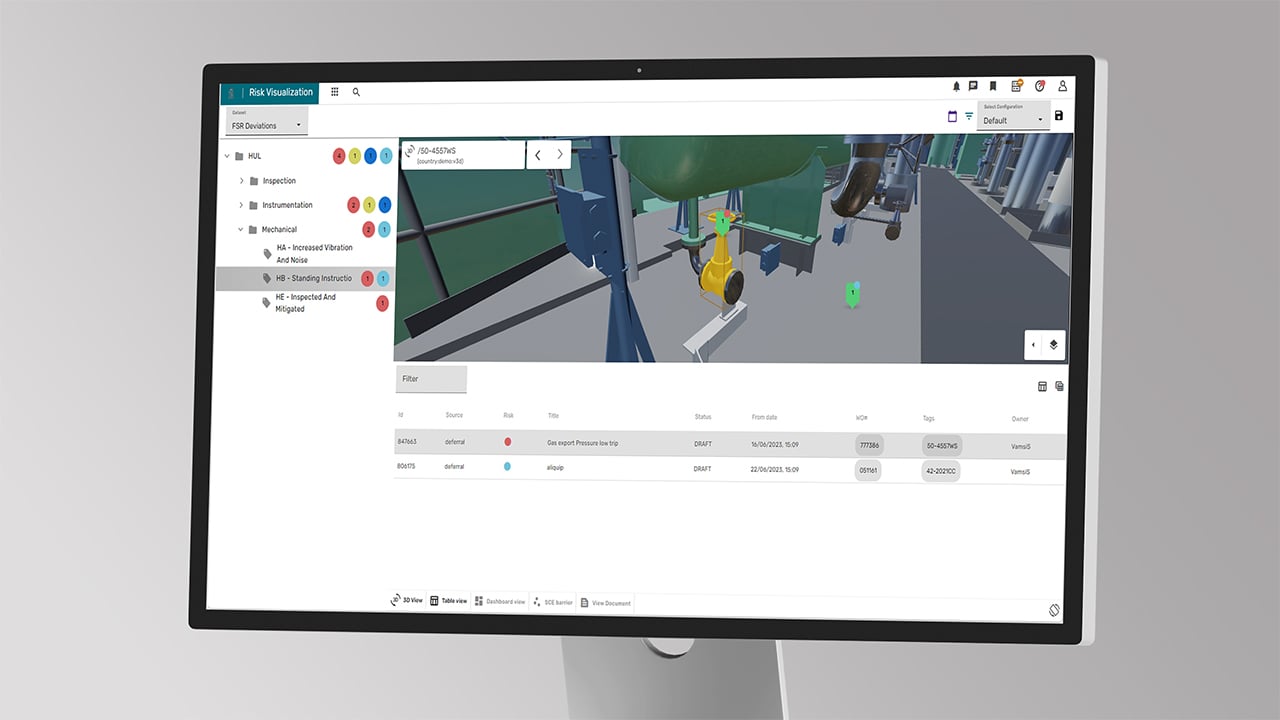

Risk visualisation

Proactive monitoring

Planning & scheduling

Isolation management

Situational awareness

Enable better, faster decision-making. Enhance the situational awareness of your asset operations by presenting each user with data relevant to their role in a single interface on any device.

Take a closer look at Kognitwin

Learn more about how our digital twin technology can help deliver operational efficiencies for your facility.

Explore our product demoMaximise business performance and drive more value

Built with our proven technology, the Industrial Work Surface is already delivering measurable value to organisations in the energy, utilities, renewables, and chemicals sectors.

3 months

Time to value

An asset has a typical digitisation time of 3 months, enabling rapid scaling across the enterprise.

85%

Users are more efficient

With one system to plan, execute and close out work, 85% of users feel more efficient.

25,000+

Users, worldwide

At-scale delivery of digital twin technology to integrated energy companies.

See why industry leaders are adopting Kognitwin

This new way of working will enable our teams to learn from past events, predict future events, and prescribe a path forward to optimise production and equipment performance automatically, maintaining safe and energy-efficient operating parameters without manual intervention. The Industrial Work Surface is the cornerstone to our future ambitions.

James Maguire, Business Transformation Manager, LNG Canada

In my first year of using the digital twin, the Nyhamna teams – together with our partner Kongsberg Digital – developed use cases with a full line of sight to reduce our operating cost by about three million US dollars, which actually beats the investment cost. And, this is just the start of our digital transformation journey.

Rolf Einar Saeter, Business Improvement and Technology Manager, Norske Shell

By integrating all our systems and data into one platform, the digital twin empowers us to improve the risk assessment of all activities at Nyhamna. It helps us achieve our goal of having zero incidents or leaks.

Torstein, Shift Supervisor, Nyhamna, Shell

Through the use of digital twin technology with embedded simulators and Artificial Intelligence, we can effectively adopt a remote operating model. It has allowed us to streamline operations, resulting in a more effective workforce that has a lower safety exposure.

Nilesh Sarin, IT Manager, LNG Canada

As reliability engineers, people in my role spend hours going through huge amounts of data. How can we check everything to ensure the technical integrity of the plant and secure availability? It’s a huge responsibility. Now, we've simplified and even automated parts of the process with the Twin. It's a true game-changer.

Alfred Nerland, Reliability & Digital Engineer, Shell