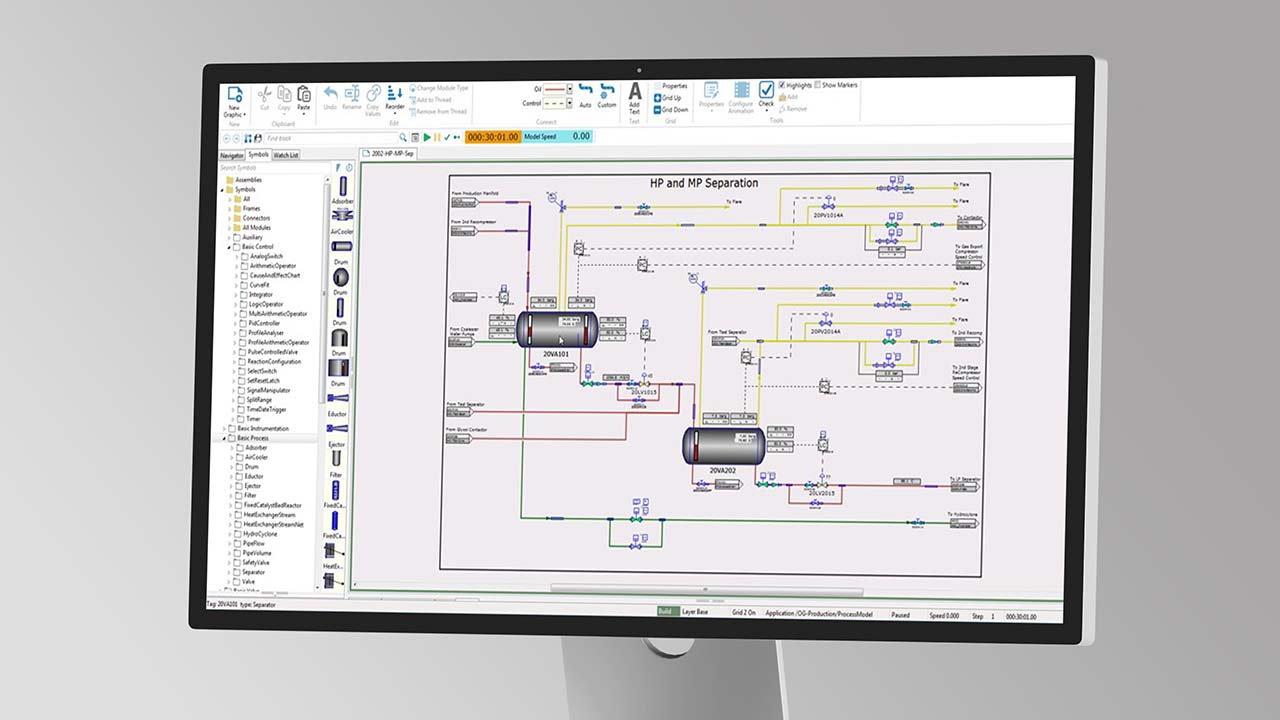

K-Spice

A flexible dynamic processing simulator that adapts to the evolving needs of your project, supporting detailed design, verification, and optimisation of processes and control systems from front end engineering design (FEED) to operations.

High-fidelity dynamic processing simulation

A flexible dynamic processing simulator that adapts to the evolving needs of your project, supporting detailed design, verification, and optimisation of processes and control systems from front end engineering design (FEED) to operations.

Maximise lifecycle value with dynamic simulation

K-Spice® dynamic simulation software empowers users to perform detailed engineering tasks, including process design verification, control and safety analysis, debottlenecking, and design optimization.

Supporting detailed design, verification, and optimisation

How K-Spice can support your objectives

Dynamic process simulation

Advanced simulation

Versatility through dynamic process simulation

Digital twins are emerging as an industry standard, driving innovation and operational excellence. Operators seek frameworks to digitise asset management, foster collaboration, optimise resource utilisation, and achieve autonomous operations.

However, successful digital transformation requires a cultural shift alongside technological advancements. The new operating model must integrate these dimensions for optimal results.

Leading heavy asset operators globally rely on K-Spice to drive efficiency, reduce costs, compress project schedules, improve safety, and create valuable learning opportunities.

Market-proven value for major industrial organisations around the world

Built with our proven technology, K-Spice is already delivering measurable value to organisations in the energy, utilities, renewables, and chemicals sectors.

+300

Dynamic simulation studies

K-Spice is widely used by industry specialists from Kongsberg Digital and its partners to deliver asset-specific dynamic simulation studies.

+100

Customised operator training simulators

K-Spice connects its dynamic process model to a replica of the plant’s actual Integrated Control and Safety System (ICSS), creating realistic operator training simulators (OTS). These OTS allow operators to safely train on all operational modes. K-Spice can also integrate with generic training simulators and includes robust assessment tools to ensure high-quality training.

+20

Real-time production assurance solutions

Real-time models, powered by K-Spice and LedaFlow, integrate sensor data and predictive calculations for a complete production overview. This data and dynamic model support informed decision-making, preventing problems and optimizing production and performance. Look-ahead, planning, and what-if modes further enhance predictive capabilities.

See why industry leaders are adopting dynamic simulations.

For me, the strength of Kongsberg Digital's simulators is the visualisation. It gives you a visual representation of what you're working with— and you can see and move through a known landscape.

Andreas Johannesen Senior Engineer, Ops Process, Equinor

This new way of working will enable our teams to learn from past events, predict future events, and prescribe a path forward to optimise production and equipment performance automatically, maintaining safe and energy-efficient operating parameters without manual intervention. The Industrial Work Surface is the cornerstone to our future ambitions.

James Maguire, Business Transformation Manager, LNG Canada

This provides a more efficient and safer work preparation process, leaner communication across teams and disciplines, reduction of meetings, faster ways to locate equipment in heights, less data crosschecks between applications, and less logistics and time spent on field inspections.

Tommy, SPC and Turnaround Supervisor, Shell

I have seen and felt the superpower of these tools.

Hilde Hongset Gauslaa, Leader, Simulator Support Center, Equinor

Simulation in digital twins

Kognitwin Simulation

Empowering operators with a virtual representation of their assets, enabling them to simulate and analyse facility behaviour before implementing changes.

LedaFlow

Advanced transient multiphase flow simulator designed to optimise continuous flow for oil, gas, CO2, hydrogen, and steam.

K-Spice

Dynamic process simulation software enabling detailed engineering tasks, including process design verification, control and safety analysis, debottlenecking, and design optimization.