LedaFlow-FieldTwin integration

The combined power of FieldTwin's visualization and LedaFlow's simulation capabilities creates a more efficient and collaborative workflow, leading to better-informed decisions during the critical early stages of a project.

improving the efficiency of concept development for flow assurance teams

The combined power of FieldTwin's visualization and LedaFlow's simulation capabilities creates a more efficient and collaborative workflow, leading to better-informed decisions during the critical early stages of a project.

Delivered by

Databricks is the data and AI company. More than 10,000 organizations worldwide — including Block, Comcast, Condé Nast, Rivian, Shell and over 60% of the Fortune 500 — rely on the Databricks Data Intelligence Platform to take control of their data and put it to work with AI. Databricks is headquartered in San Francisco, with offices around the globe, and was founded by the original creators of Lakehouse, Apache Spark™, Delta Lake and MLflow.

Bridging the subsea facilities gap

Subsea Twins are critical to create a complete model of the field from the wellbore to the topside processing facility.

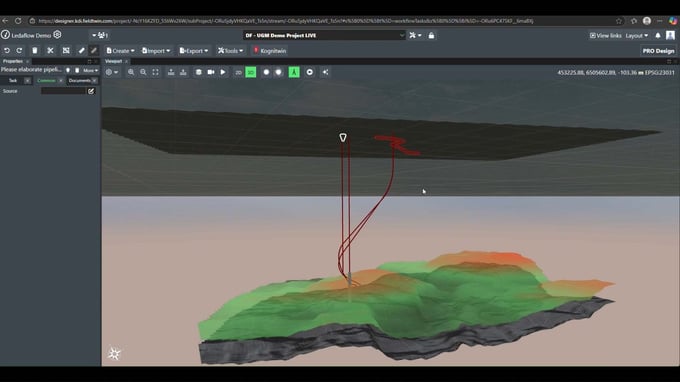

FieldTwin is an industry-standard visualization tool that's well-proven for subsea development. The integration with LedaFlow significantly optimizes the concept selection phase for flow assurance teams by providing a shared, easy-to-use 3D visualization platform.

Design, simulate, and optimize subsea concepts within a single, streamlined workflow in FieldTwin and LedaFlow

Breaking down data silos to create unified, collaborative, and efficient workflowss for seamless information sharing - from initial design stages to final analysis.

- Export subsea flow paths directly from FieldTwin ready for LedaFlow to consume

- Trim, lock and manage flow paths for LedaFlow directly from FieldTwin to either isolate elements of the network for detailed analysis, or provide large networks for LedaFlow to model

- Upload and manage PVT data against your flow paths and to form basis for LedaFlow simulation

- Define key parameters such as diameters, ambient and flowing pressures and temperatures as well as heat transfer and boundary conditions within FieldTwin for LedaFlow to utilize

- Run parametric studies in LedaFlow and view results directly the FieldTwin interface

FieldTwin integrates directly with LedaFlow, providing an easy-to-use 3D canvas to build and test subsea designs coupled with the power and accuracy of the LedaFlow multiphase flow simulator:

- Comprehensive and complimentary design and engineering tools

- Data-driven simulation enabling optimization of development options

- Launch LedaFlow studies directly from FieldTwin to test different concepts and flow assurance variables such as flow rate and pipeline diameter

- Avoid duplication of efforts for your Concept and Flow Assurance engineers with a centralized source of relevant metadata for the model inputs

- Empower robust decision making for your concept selection by enabling simulation results and comparisons in context of your 3D FieldTwin model

See the integration at work

Build

Run sensitivity

Manage

Building a LedaFlow model from FieldTwin

See how to improve the efficiency of concept development for Flow Assurance teams.

Reduce data gathering, ensure centralized version of the data and remove duplicate entries.

View results from the simulator in context of the 3D model for robust decision support

Learn more about FieldTwin with LedaFlow

Reach out to be contacted by our product specialist for deeper insight

About FutureOn and Field-Twin®

FieldTwin is a powerful, easy-to-use design, collaboration and visualisation platform that

can quickly and efficiently bring energy developments to life.

As a collaborative platform, FieldTwin:

- Improves efficiency and managing costs through better resource management.

- Streamlines design workflows by fostering collaboration and breaking down data silos.

- Accelerates project timelines, reducing pre-FEED and concept planning time by at least 60%.

- Delivers end-to-end value from planning to decommissioning for better, faster outcomes at a lower cost.

Simulation capabilities

Kognitwin Simulation

Empowering operators with a virtual representation of their assets, enabling them to simulate and analyse facility behaviour before implementing changes.

K-Spice

Dynamic process simulation software enabling detailed engineering tasks, including process design verification, control and safety analysis, debottlenecking, and design optimization.

LedaFlow

Advanced transient multiphase flow simulator designed to optimise continuous flow for oil, gas, CO2, hydrogen, and steam.