Simulator-driven insights

In complex industrial systems, early signs of failure are often missed—lost in the noise of data, hidden behind normal-looking measurements, or simply ignored by static thresholds. Simulator-driven condition monitoring allows you to detect issues before they become critical.

Detecting the hidden signals of failure

In complex industrial systems, early signs of failure are often missed—lost in the noise of data, hidden behind normal-looking measurements, or simply ignored by static thresholds. Simulator-driven condition monitoring allows you to detect issues before they become critical.

Limitations of current monitoring systems

Reactive monitoring systems

Reactive monitoring systems leave operators no time to prevent damage or downtime, forcing a constant state of damage control.

Sensor drift

Slow degradation of sensors causes drifts that doesn’t trigger alarms, but silently erodes a plant's performance and reliability.

Siloed data

Siloed systems often traps critical data; maintenance logs, process trends, and operator notes are scattered and prevents a complete picture of operations.

Static thresholds and disconnected monitoring simply aren't enough for today's complex industrial environments. The intricate interactions between equipment create subtle patterns that are easily missed without a unified, dynamic approach to monitoring.

Introducing the solution

Build the model

Create a digital reference, using engineering data, process design documents, and operational experience. The goal is to create a high-quality dynamic simulation that reflects the intended plant behavior.

From offline to live

The simulator is deployed into the digital twin and connected to real-time field data. Live plant signals are mapped to the model’s boundaries and ensures all connections are technically sound. This ultimately verifies that the simulator now responds to actual operating conditions, not just design assumptions.

Model tuning

Through thorough analysis, closing the gap between the model and the real plant. This process improves the model's quality, making it accurate enough to serve as a live benchmark.

Calibrating monitoring logic

As the live model runs, residual data is collected over a baseline period. This allows the system to learn what normal deviations look like and then automatically calibrate its thresholds.

The result is a condition monitoring solution that scales from a single system to thousands of transmitters. And the tuning work itself improves both the simulator and the plant, surfacing issues that might otherwise go unnoticed. Most importantly, this creates a solid foundation for what comes next.

Model-driven diagnostics, pattern recognition, and smarter operational insight directly inside the twin. This delivery model doesn't just end with calibrated alarms. It opens up a path forward.

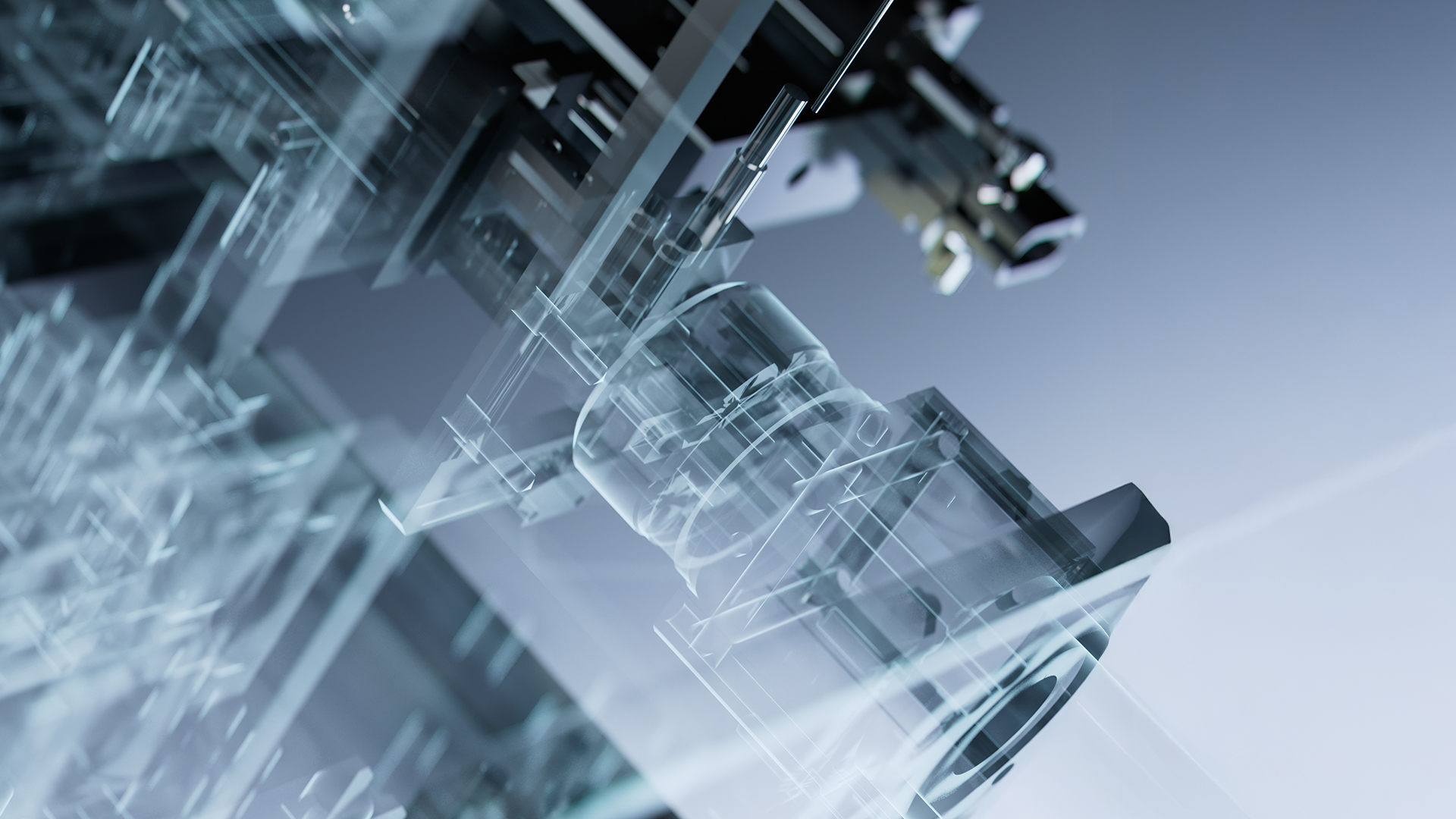

Advanced simulation with digital twin technology to generate more value

Model and simulate production processes and assess control systems with state-of-the-art dynamic simulators for actionable insights and control.

Explore simulator-driven condition monitoring

Introduction

Structure and delivery

Fault pattern library

Working demo

In complex industrial systems, failure rarely comes without warning, but too often the early signs go unnoticed, lost in noise, missed by thresholds or hidden behind normal looking data.

See how we compare every real-time measurement against its expected behavior continuously and at scale. This is the power of simulator driven condition monitoring.

Maximise business performance and drive more value

Built with our proven technology, the Industrial Work Surface is already delivering measurable value to organisations in the energy, utilities, renewables, and chemicals sectors.

3 months

Time to value

An asset has a typical digitisation time of 3 months, enabling rapid scaling across the enterprise.

85%

Users are more efficient

With one system to plan, execute and close out work, 85% of users feel more efficient.

20,000+

Users, worldwide

At-scale delivery of digital twin technology to integrated energy companies.

Simulation in digital twins

K-Spice

Dynamic process simulation software enabling detailed engineering tasks, including process design verification, control and safety analysis, debottlenecking, and design optimization.

LedaFlow

Advanced transient multiphase flow simulator designed to optimise continuous flow for oil, gas, CO2, hydrogen, and steam.

Kognitwin Simulation

Empowering operators with a virtual representation of their assets, enabling them to simulate and analyse facility behaviour before implementing changes.