- Products

- By Industry →

- Energy →

- Oil & Gas

Lorem ipsum dolor sit amet consectetur. Donec lorem ultrices magna massa vulputate

- Renewables

Lorem ipsum dolor sit amet consectetur. Donec lorem ultrices magna massa vulputate

- Maritime →

- Merchant Marine/Shipping

Lorem ipsum dolor sit amet consectetur. Donec lorem ultrices magna massa vulputate

- Offshore

Lorem ipsum dolor sit amet consectetur. Donec lorem ultrices magna massa vulputate

- By Business Function →

- By Solution →

- All Resources →

- Blogs →

- News →

- Trust Centre →

- Legal →

- Kognifai maritime ecosystem →

- Terms of use →

- Support & SLA →

Lorem ipsum dolor sit amet con sectetur done.

- Kognitwin Energy →

- Terms of use →

- Support & SLA →

Lorem ipsum dolor sit amet con sectetur done.

- Compliance →

- Security →

- Privacy →

- All Resources →

- Trust Centre →

- Legal →

- Kognifai maritime ecosystem →

- Terms of use

- Support & SLA

Lorem ipsum dolor sit amet con sectetur done.

- Kognitwin Energy →

- Terms of use

- Support & SLA

Lorem ipsum dolor sit amet con sectetur done.

- Compliance

- Security

- Privacy

- Use cases

- Resources

- Why Kongsberg Digital?

- Contact

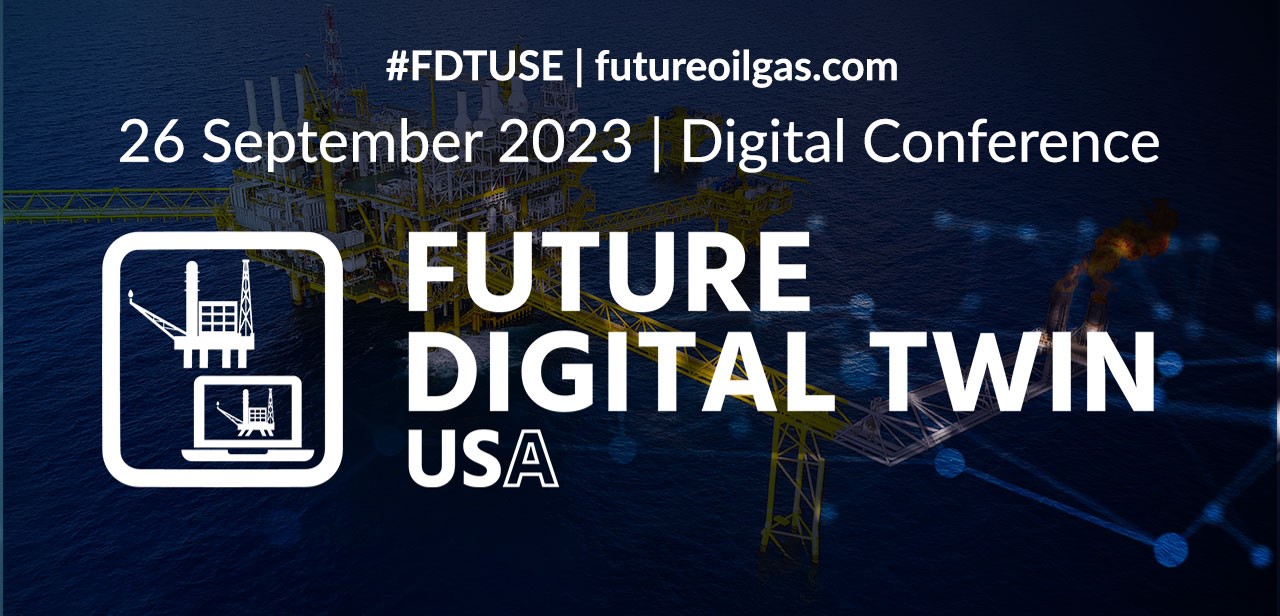

June 25, 2024

Join us at Future Oil and Gas (Aberdeen)

June 25, 2024

Join us at Future Oil and Gas (Aberdeen)