October 24, 2025

From isolated systems to connected workers

A new era of remote and connected work

A new standard for how connected workers operate

Access to live data, contextual insights, and collaborative tools allows operations to move faster and more safely. The transformation is underway as industrial teams begin to orchestrate these capabilities, moving from isolated activities toward a unified flow of work across the organisation.

This marks more than a technological milestone: it's a new way of working. Connected workers are now part of a digital ecosystem where people, tasks, and systems are continuously aligned.

This enables connected workers to:

- Access real-time data from the field, including asset condition, operational parameters and work orders.

- Collaborate instantly across shifts, departments, and locations.

- Receive contextual insights and recommendations from intelligent systems that guide your next move.

- Complete work safely and efficiently, often without needing to enter hazardous zones

Connectivity used to be a barrier. Now, its your competitive advantage.

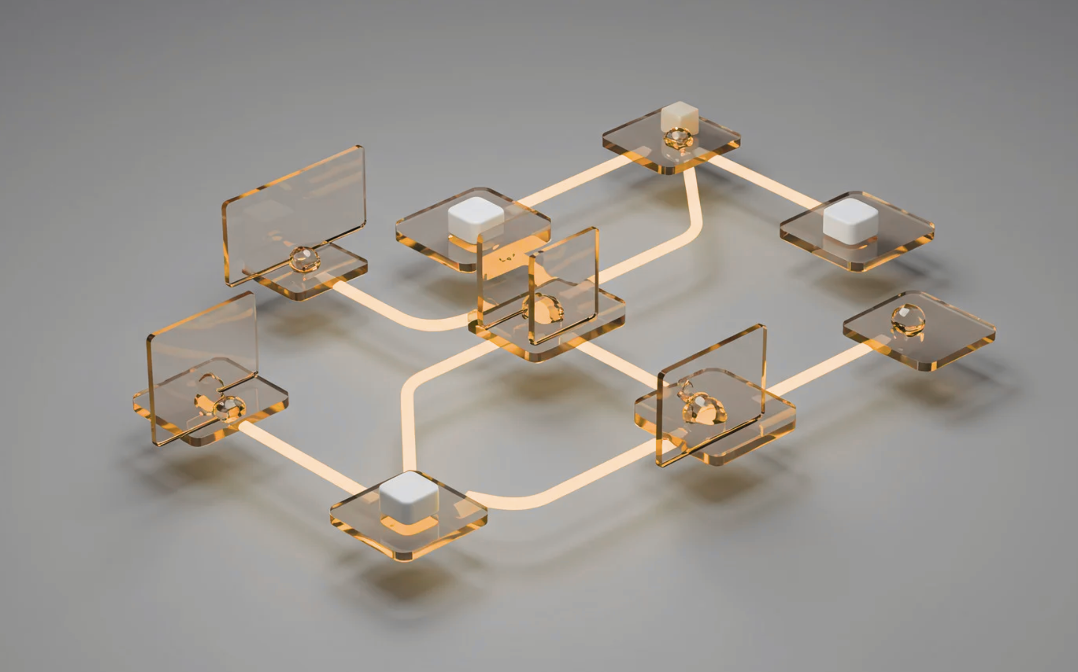

The Industrial Work Surface

Kongsberg Digital's Industrial Work Surface forms a single operational layer that links and contextualises data across the current digital landscape. It integrates sensors with enterprise systems and continues to develop as new data sources and automation tools are introduced.

It is a unifying work surface that connects tasks, people, and insights across the organisation. Instead of jumping between systems, workers operate in one continuous environment where tasks flow naturally, from initiation to execution to completion.

The Industrial Work Surface is a digital layer that connects control systems, asset data, and field operations in one environment. It brings together information from existing systems into a unified interface where work orders, sensor data, and insights are continuously available and updated in real time.

Extending reach without compromising safety

Safety, logistics, and accessibility remain constant challenges in heavy-asset operations. Remote capabilities can help you manage these challenges more effectively.

Maintenance teams can diagnose issues before sending personnel on-site. Operators can oversee multiple assets from a central hub, and supervisors can approve work and monitor progress remotely, without needing to be in the field.

This shift has a direct impact on:

- Performance: Higher asset utilisation and less downtime

- Productivity: Less travel and faster execution

- Organisational value: Fewer people in hazardous areas

- Regulatory compliance: Better safety and oversight

Video: Empowering remote planners with a digital twin

Why is this so important for remote and connected workers?

The connected workforce represents a strategic shift, not only an operational improvement.

Profitability in heavy-asset industries depends on performance and productivity. Every minute of uptime counts, and every maintenance delay or operational blind spot translates into cost.

At the same time, organisational and strategic value are becoming key differentiators. Modern digital tools help attract and retain top talent by enabling safer, smarter, and more fulfilling work environments.

Heavy-asset industries are entering a new phase where connectivity, intelligence, and collaboration are becoming the key drivers of operational success. The connected and remote worker is no longer a futuristic vision; it’s the cornerstone of modern operations.

Industrial software now connects the field with the office. Every decision, from the control room to the front line, becomes data-driven, coordinated, and precise.

As industrial systems mature, this connected foundation will support greater automation, integration with robotic field units, and increasingly autonomous decision support.

What are the challenges in remote and connected work?

How can industrial teams move from fragmented work to connected operations?

What changes when operations run on a unified industrial surface?

Sign up to stay updated

Bridge the digital and physical realm with the Internet

Kongsberg Digital's IoT concept revolves around seamlessly integrating advanced digital solutions with the physical world to empower asset-intensive industries. By harnessing real-time data from interconnected sensors and devices, we enable.

Learn moreAuthor

Kongsberg Digital

Kongsberg Digital is a provider of next-generation software and digital solutions to customers within oil and gas, chemicals and offshore wind. Its Industrial Work Surface, powered by the Kognitwin® platform, is redefining how industries work with data, insight and decision-making.