September 3, 2025

Why Contextualisation Is the Hard Problem in Industrial Data (and How to Solve It)

Why industrial data fails to deliver insight

Energy operators are swimming in data: historian time series, equipment tags, P&IDs, work orders, operator logs, and maintenance manuals. Yet for all its abundance, this data rarely delivers the insight leaders expect. Why? Because it sits in silos—fragmented across systems, formats, and functions.

Without meaningful relationships—semantic links connecting sensors to assets to maintenance events—data becomes nearly impossible to query efficiently, diagnose problems quickly, or align operational activity with engineering reality. As we often note, digital twins can only deliver a true “single source of truth” when they contextualise and visualise data across systems.

What “Contextualisation” really means

Contextualisation is not aggregation. It is the semantic weaving together of disparate data types—time series, documents, diagrams, alarms—into a connected knowledge graph.

In this graph, every asset, sensor, work order, and procedure is represented as a node, with relationships that reflect how the real-world system operates. This enables operationally useful queries such as:

- Which pumps were running during that alarm event—and what is their maintenance history?

- What is the downtime trend of my key compressor, and how does it impact upstream throughput?

These are the kinds of questions that transform raw data into actionable operational intelligence.

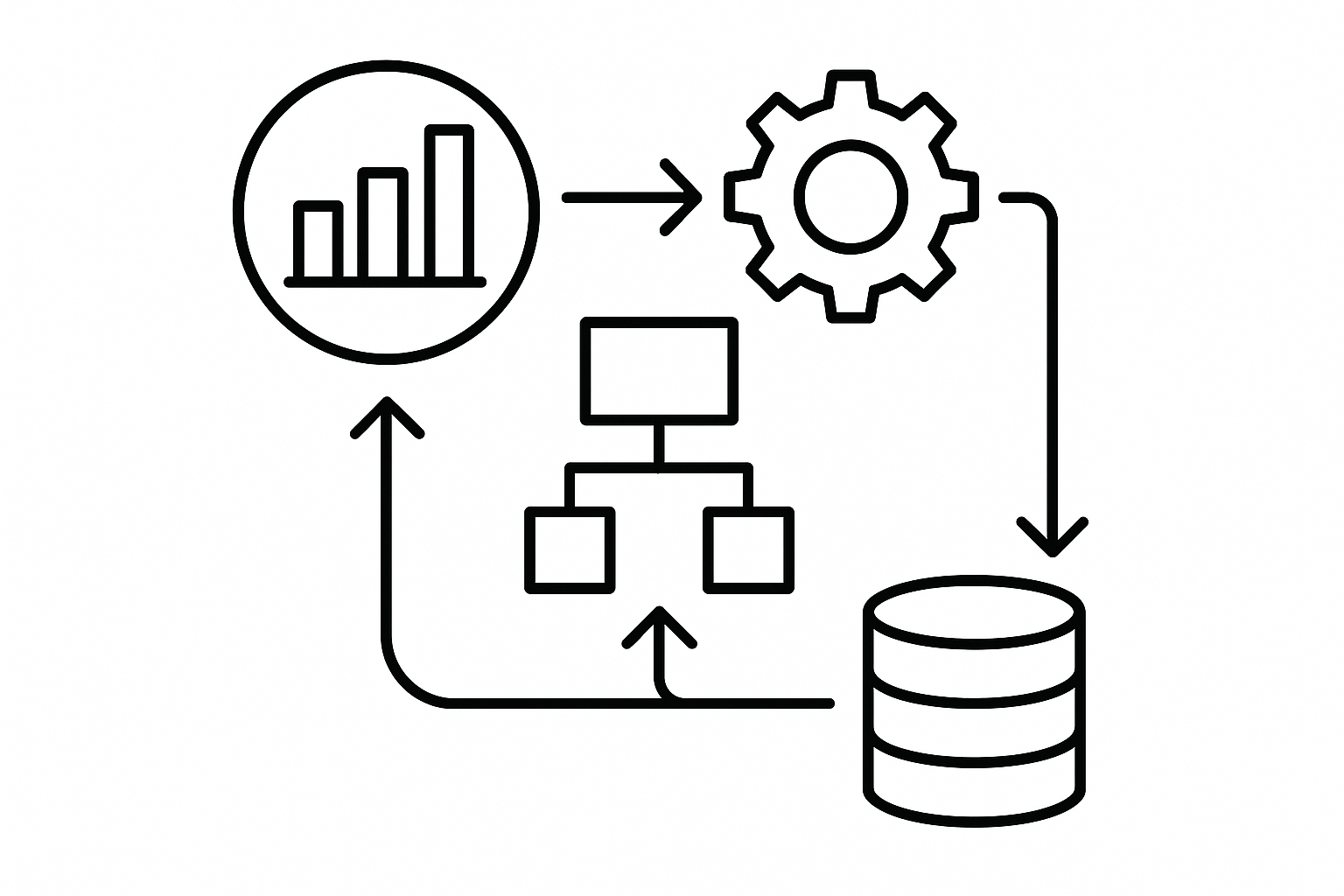

The contextualisation pipeline

Building such a system is complex, requiring both technology and governance. A proven contextualisation pipeline typically includes:

- Ingest & Normalise – Collect data from historians, engineering systems, document stores, and operator logs, then bring it into a consistent namespace.

- Entity Extraction & Linking – Apply ML, pattern matching, and domain rules to identify and connect entities (e.g., linking tag P-101 to its pump asset, alarm history, and CAD/3D location).

- Governance & Traceability – Enforce lineage and version control so that every relationship is auditable and explainable.

- Serving & Scaling – Deliver APIs, search interfaces, and graph visualisations that support day-to-day operations, analytics, and AI/ML use cases.

Why energy makes contextualisation harder

The energy sector faces unique hurdles:

- Legacy equipment and decades of accumulated formats.

- Strict regulatory and compliance requirements.

- Domain-specific semantics that differ between upstream, midstream, power generation, and renewables.

Creating semantic coherence across this landscape demands robust ontologies, industry expertise, and disciplined change management.

Kongsberg Digital: Context in action

Kongsberg Digital’s digital twin platforms are built to solve this challenge. By ingesting and semantically connecting assets, forecasts, simulations, and operational logs, they create the contextual backbone operators need for accurate and holistic situational awareness.

Even in low-digital-maturity environments, these tools unify heterogeneous data and make it operationally useful—delivering what Kongsberg Digital describes as the ability to “contextualise and visualise data” to support smarter decisions, safer operations, and more sustainable performance.

Why context is foundational

With context, energy teams can:

- Run cross-domain queries that reveal true system behaviour.

- Train AI models anchored in operational truth, not statistical artefacts.

- Accelerate incident response and strengthen audit readiness through clear lineage.

In short, contextualisation is the hidden enabler of digital transformation. Without it, industrial data remains noise; with it, operators unlock intelligence that drives performance, safety, and sustainability.

Read on to learn how Kongsberg Digital is helping operators contextualise their data to unlock real-world value.

Author

Kongsberg Digital

Kongsberg Digital is a provider of next-generation software and digital solutions to customers within oil and gas, chemicals and offshore wind. Its Industrial Work Surface, powered by the Kognitwin® platform, is redefining how industries work with data, insight and decision-making.

Related news

February 2, 2026

Stop predicting failures in chemicals. Start defining the operating envelope.

January 26, 2026

NARTC 2026: Operationalising Refiners’ Digital Ambitions

January 18, 2026

Research study: Grid data & digital adoption

November 14, 2025

Industrial intelligence: Connecting the physical and digital for the future of work