September 4, 2025

From Historians to Knowledge Graphs: Turning Tags into Decisions

Transform Raw Tags to Business Insight

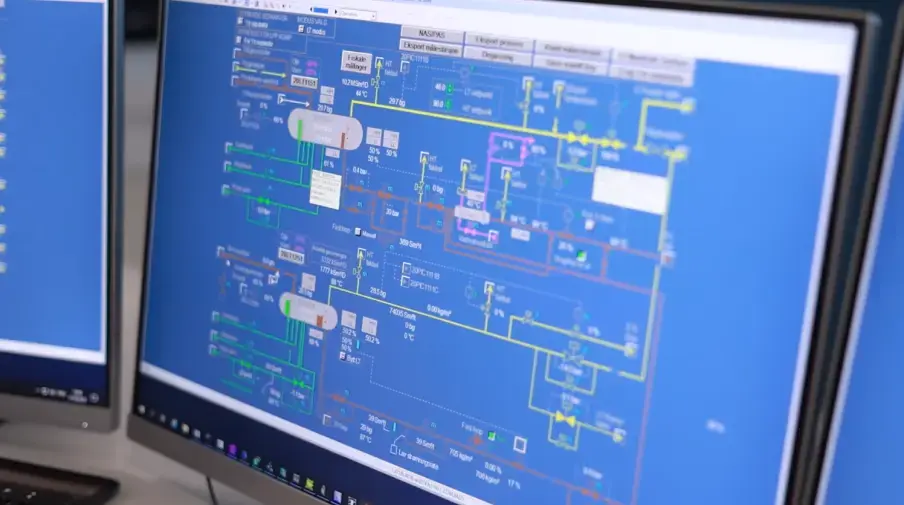

Every second, industrial historians churn out terabytes of time-series data—temperatures, pressures, flows—all tagged by sensor or equipment ID. But here’s the key: raw tags aren’t insight.

A pressure spike is meaningless unless you know which pump, which process, and what context underlies it. Without structure, operators are drowning in disconnected tags—they need a path from data point → equipment → procedure → decision.

That’s where knowledge graphs come in — visual data models that represent assets, relationships, and events as interconnected nodes. Think of knowledge graphs as structured nodes and relationships that bring clarity out of chaos.

Why Knowledge Graphs Matter for Energy

Energy facilities are complex, interconnected ecosystems. A pump shutdown can affect a compressor upstream, which impacts throughput and revenue. A knowledge graph allows you to model these dependencies explicitly, enabling root cause analysis, “what-if” simulations, and decision support.

Historian data can tell you what happened. Knowledge graphs tell you why it matters. They empower:

- Lightning-fast root cause analysis

- 'What-if' scenarios/simulations

- Context-rich decisioning, directly linking tags to maintenance, procedures, and processes

Kongsberg Digital in Action

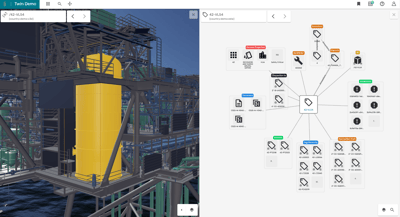

Kongsberg Digital’s dynamic digital twin platform, Kognitwin®, embeds a knowledge graph at its core. It connects live historian data, engineering documents, P&IDs, and asset hierarchies so users can navigate from a single measurement to the underlying process context. This enables operations teams to answer questions in minutes that once took hours or days.

Building the Graph: From Chaos to Clarity

Creating an operational knowledge graph means following a proven path:

- Ingest: Pull from historians, CMMS, document management, and SCADA.

- Normalize: Harmonize tags, IDs, and units.

- Model: Define asset classes, process hierarchies, and relationship rules (ISO 15926).

- Link: Use ML/computer vision to connect P&ID symbols to tags and documents.

- Serve: Make available through APIs and visual navigation in tools like Kognitwin®.

Think of it as transforming data chaos into decision intelligence.

Real-World Digital Twin Impacts in Energy Operations

This concept of an intelligence layer isn’t aspirational – it’s already happening. A major energy operator saw $1–2 million in annual savings thanks to reduced unplanned shutdowns. This is especially striking when considering that unplanned downtime can cost oil & gas companies up to $49 million annually, with even just 3.65 days of downtime translating to $5 million in losses.

A 2025 peer-reviewed literature review of digital twin implementations across industrial sectors shows consistent reductions in both scheduled and unscheduled downtime—thanks to capabilities like real‑time anomaly detection, predictive maintenance, and enhanced process modeling.

Key Takeaway

Knowledge graphs are technology enablers. They transform raw historian feeds into actionable operational intelligence. They’re the connective tissue between data sources and strategic decision-making. Contextualizing tags within their broader operational landscape empowers operators to move beyond data overload—into confident, fast decision action.

In today’s energy world, data is abundant—but decisions, fast and well-informed, are the real competitive edge.

Author

Kongsberg Digital

Kongsberg Digital is a provider of next-generation software and digital solutions to customers within oil and gas, chemicals and offshore wind. Its Industrial Work Surface, powered by the Kognitwin® platform, is redefining how industries work with data, insight and decision-making.

Related news

February 2, 2026

Stop predicting failures in chemicals. Start defining the operating envelope.

January 26, 2026

NARTC 2026: Operationalising Refiners’ Digital Ambitions

January 18, 2026

Research study: Grid data & digital adoption

November 14, 2025

Industrial intelligence: Connecting the physical and digital for the future of work