4 March 2022

Kongsberg Digital drives sustainable change with new possibilities in Carbon Capture and Storage (CCS)

Kongsberg Digital is delighted to move LedaFlow forward on the innovation front as part of the two-year GELECO2 Joint Industry Product with CMG Canada to simulate CO2 injection into reservoirs. Together with CLIMIT, Norway’s national research program for CCS technologies, this initiative is supported and funded by key industry actors.

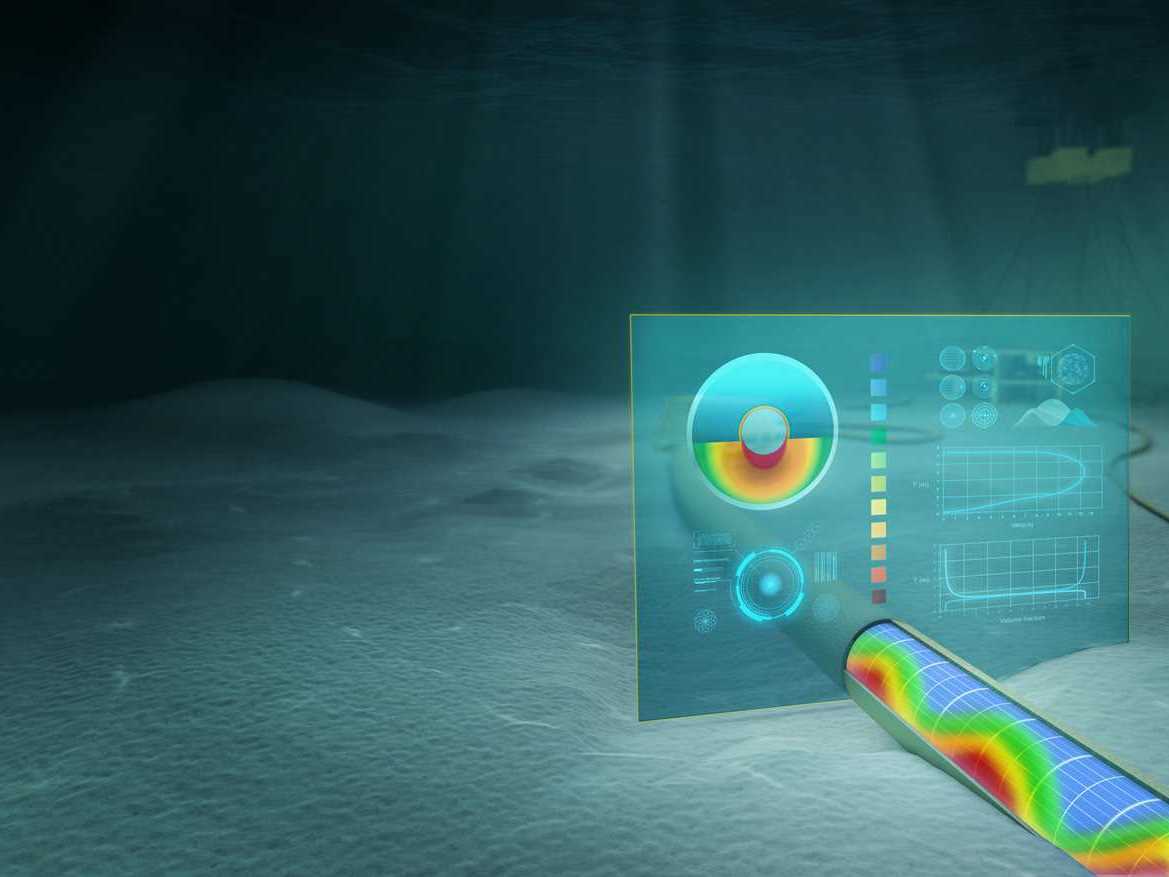

The integration of Kongsberg Digital’s product LedaFlow for advanced transient multiphase flow simulation and CMG’s world-leading Reservoir Simulator GEM is an industry first and an exciting advancement in the ability to simulate carbon capture and storage (CCS) efforts in various operational scenarios.

With further innovation of LedaFlow’s solution, challenges to carbon capture and storage methods can be addressed head on. While LedaFlow has been used to simulate multiphase flow for wells, flowlines, and processing facilities, it will now be utilized in an innovative project to identify new opportunities for achieving decarbonization at scale. This new project will look at integrating with CMG’s Reservoir Simulator for further simulation to accurately predict well responses and ensure safer, more efficient storage of carbon dioxide underground.

Why CCS?

Renewed climate discussions andnet-zero ambitionshave put the focus on the potential of carbon capture and storage when backed by new technologies and innovation. For the heavy asset industry, CCS has been proven effective in helping to reduce the amount of CO2 that is emitted during operations by capturing it in production phases before it is released into the atmosphere and then transporting it elsewhere for long-term storage.

Carbon capture can achieve 14 percent of the global greenhouse gas emissions reductions needed by 2050 and is viewed as the only practical way to achieve deep decarbonization in the industrial sector. Center for Climate and Energy Solutions

Carbon dioxide that is captured can be used for oil recovery, re-used in manufacturing processes such as fertilizer production, transformed into building materials, or stored in deep underground geological formations including oil and gas reservoirs and deep saline formations. By removing CO2 from processes and injecting it underground for long-term storage, emissions are majorly reduced and when this is used alongside renewable energy solutions, climate goals are easier to achieve and maintain.

Challenges to co2 capture, transport, and storage

While CCS approaches offer an effective way to remove carbon dioxide and achieve operations that are closer to net zero, there are some challenges to keep in mind.

- High costs: Few industry facilities are equipped with CCS technology. Implementing this technology is expensive and leads to higher electricity and maintenance costs.

- Long-term storage capacity: Storage for captured CO2 is not available in every country, and it is difficult to calculate the actual capacity of storage sites.

- Safety risks: If CO2 leaks were to occur at an injection site, the surrounding environment and people would be at risk. Leaks originating from rock layer fractures could contaminate soil and groundwater and may even trigger seismic events.

- Public perception: Carbon storage locations near inhabitable areas may be perceived as imposing potential health and environmental risks to nearby communities.

- Lack of integrated existing reservoir and wellbore simulators: To date, wellbore models provide an overly simplified view of reservoir responses to CO2 injection that are not sufficient for operational planning, particularly during the startup and shut down phases.

Innovation for a better tomorrow

Kongsberg Digital and CMG’s innovative CCS project will enable a truly integrated simulation that virtually models the injection and storage of carbon into reservoirs, providing opportunities to address these challenges directly. By being able to simulate CO2 injection processes before execution, broader safety risks and environmental concerns can be mitigated while the use of simulation technology holds the potential to significantly lower costs and maximize the effective use of storage capacity for long-term CO2 capture.

Flow assurance and wells teams need to better understand the transient effects related to CO2 injections, particularly in novel CO2 injection situations. The ability to model, understand, and simulate well responses and interactions with near-well reservoir regions can facilitate significant savings by reducing the risk of unplanned shutdowns, hydrate formation, well plugging, and unexpected system damage.

The compelling business case for CCS is already here, and a commercially available integrated transient wellbore and reservoir modelling system for CCS will be a game changer as organizations and countries scramble to find more affordable, effective, and safe solutions to decarbonize the industrial sector globally.

Deep domain and digital knowledge paired with trusted partnerships and the latest technologies ensure that Kongsberg Digital continues to provide cutting-edge transformative solutions for the heavy asset industry.